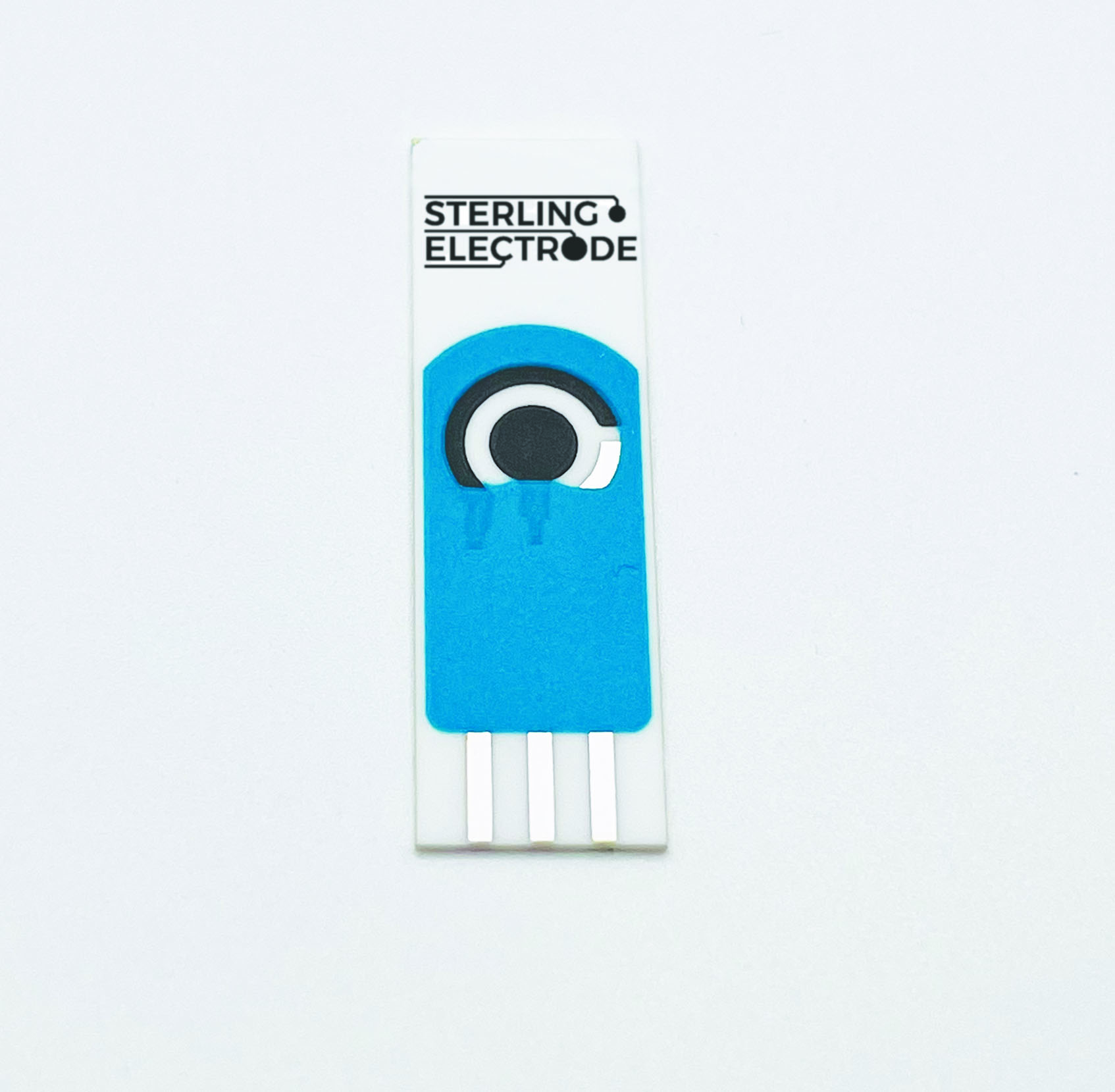

Manufacturing Custom Screen Printed Electrodes

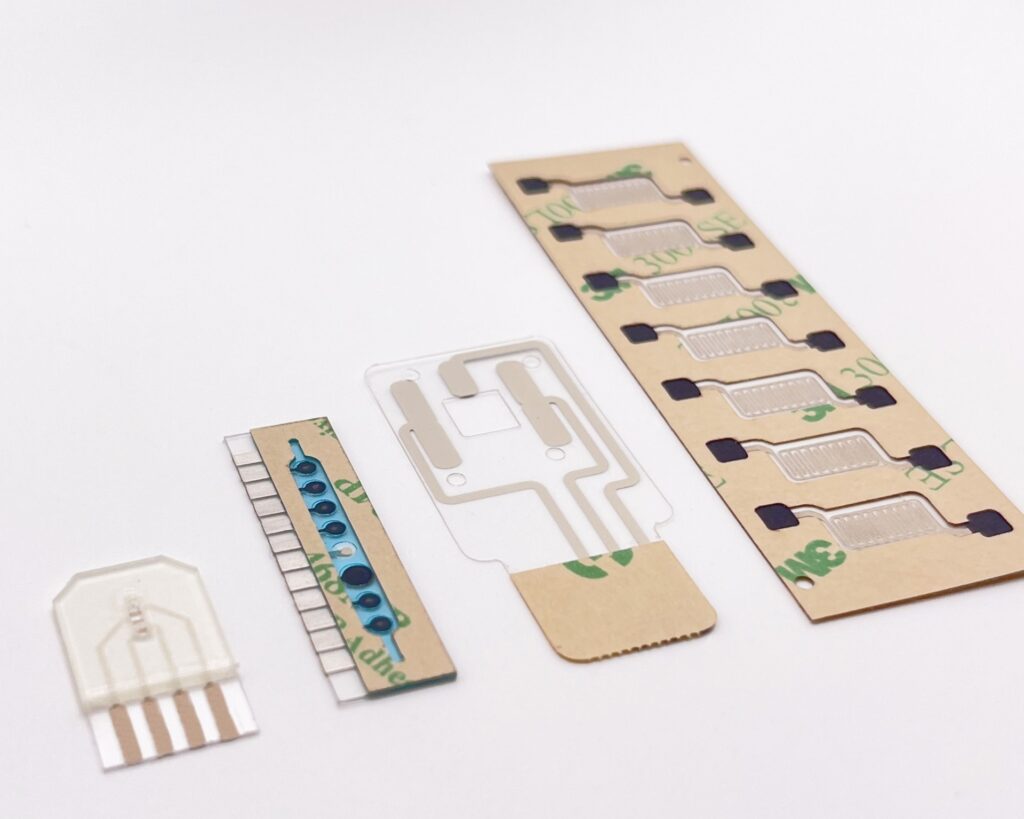

Sterling Electrode designs and manufactures custom Screen Printed Electrodes (SPEs). Generally, our customers develop an analytical method based on commercially available, stock SPEs. Then, as their project progresses, our customers need electrode customization for their specific application. That is where we step in to help. Our team has many years of experience fabricating custom screen printed electrodes. We screen print conductive inks at our manufacturing facilities in the USA, Asia, and Europe. Electrodes are cut to final size and shape with laser cutting, drag knife cutting, or die cutting. Pressure sensitive adhesives, such as 3M adhesives, can be added to the electrodes when required.

Inks and Substrates for Custom Screen Printed Electrodes

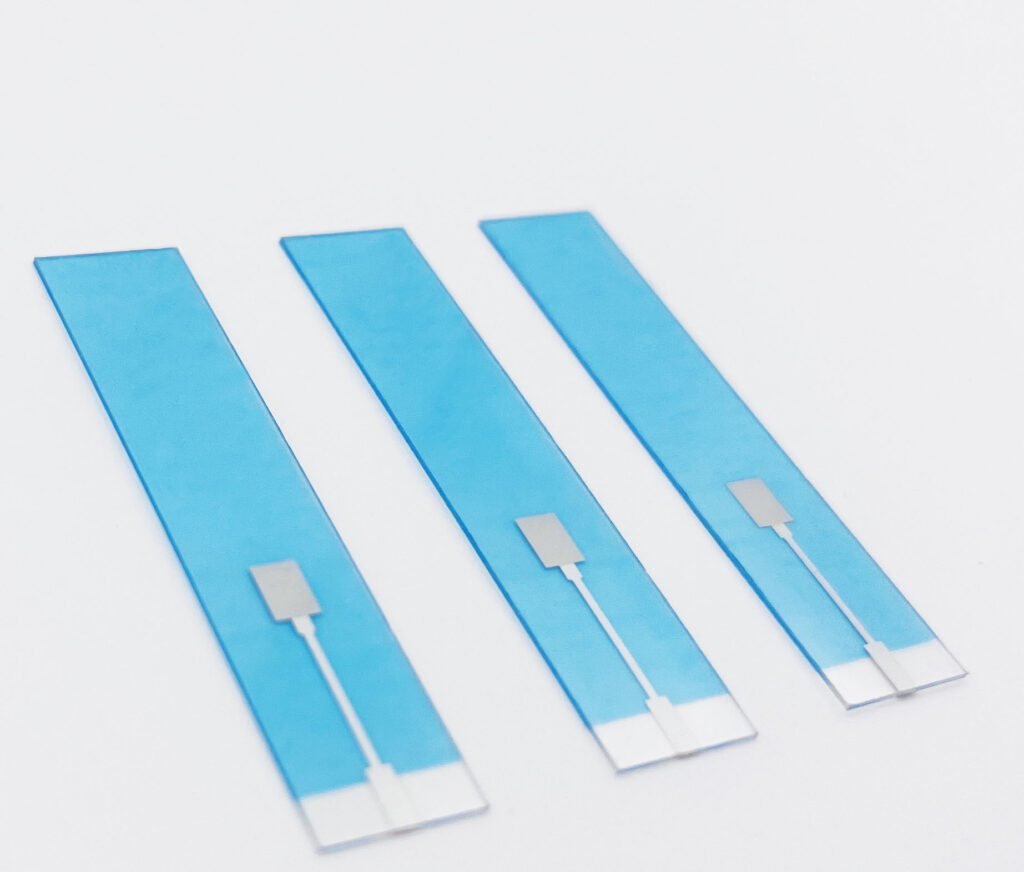

One of the most common requests that Sterling Electrode receives is to fabricate SPEs using a specific bill of materials including special conductive inks and substrates. We have experience printing conductive silver ink, silver/silver chloride ink (83/17, 80/20, and 50/50 are common Ag/AgCl mixtures), graphite carbon ink, Prussian blue ferrocyanide ink, graphene inks, platinum inks, gold inks, transparent conductive PDOT inks, and other specialty conductive inks. Sterling Electrode can print these inks on almost any substrate that is required for your custom sensor application. We commonly print on heat stabilized PET, polyimide, polycarbonate, allumina, glass & silicone wafers. We can screen print on individual sheets or wafers, or we can provide roll-to-roll printing when it is required for very high volume applications.

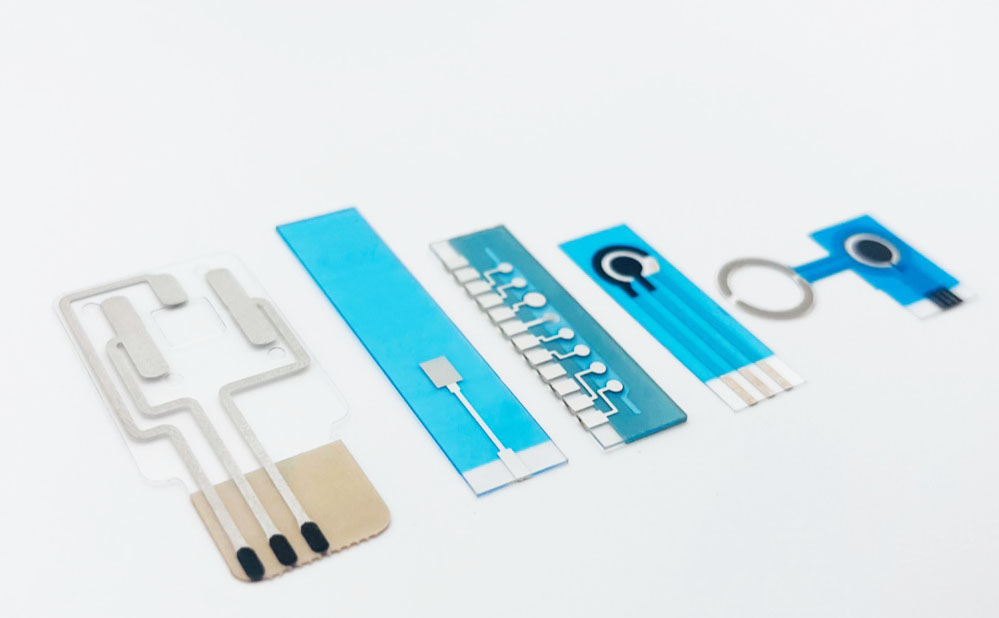

Custom Form Factors for Screen Printed Electrodes

Sterling electrode can manufacture SPEs in any shape or size required. Many of our customers want their custom screen printed electrodes to be compatible with commercially available potentiostat equipment. Other customers need a specific electrical contact layout to mate with pogo-pins, ZIF connectors, or edge connectors. This means that we can use industry standard connector designs so that the SPEs plug right into your existing potentiostat, or the SPEs can be designed to mate with your custom interface. The electrode area is where most of the unique customization happens. We can change the dimensions and geometries of the working electrode (WE) auxiliary electrode (AE) or reference electrode (RE) as required for your specific application. We commonly manufacture annular electrodes, interdigitated electrodes, and other specialty electrode configurations.

Manufacturing Locations for Custom SPEs

Sterling Electrode manufactures custom screen printed electrodes in ISO 9001 & ISO13485 facilities in Arizona, Asia, and Europe. We are set up to provide prototyping and scale-up manufacturing in the southwest United States. Our customers really value the responsive engineering service and quick answers to questions that we can provide with our team in Arizona. This allows us to successfully guide our customers through iterative prototyping, scale-up and commercialization. For applications that require over 10k SPEs per month, we usually move manufacturing offshore to Asia or Europe depending on the exact product requirements.

How do you get started on your Custom Screen Printed Electrode project?

To get started on your project, we will need drawings that show the SPE that you need us to make. AutoCAD DWG/DXF drawings are preferred, but we can also work from well dimensioned PDF documents. Please make sure your drawings show the outside dimensions of the SPE, the inks and substrate that are required, and all electrode locations & geometries. Once you send us your drawings, it will take us 1-2 business days to review and provide you with a quote. We look forward to working with you! Please send your drawings to sales@sterlingelectrode.com or fill out our contact form.