Integrating Screen Printed Electrodes into Microfluidic Devices

Screen Printed Electrodes are used to measure currents and potentials inside of a micro fluidic device. These electrical signals can tell us information about drug concentrations, chemical reaction progressions, and other relevant parameters. Many microfluidic applications require a lot of customization for the electrodes to function correctly. Sterling Electrode LLC provides our customer with guidance on the best materials, geometries, and manufacturing processes.

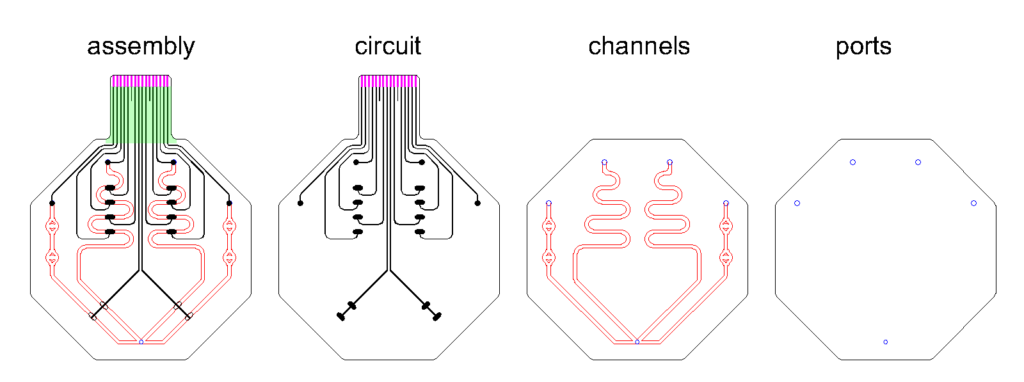

Some common electrode materials used in microfluidic applications are: Ag/AgCl (Silver/Silver Chloride), graphite carbon, Platinum, Gold, and Prussian Blue. We can integrate these materials into flow cells made of substrates such as PET, PDMA, TPU, polycarbonate, acrylic, and specialty hydrophilic/hydrophobic substrates made by 3M. Fluid channel geometries and construction materials will determine fluid flowrate. Asymmetrical junctions and splits in the channel are used to separate and mix reagents in the channel.

Our micro fluidic devices are used in applications such as bio-monitoring of drug analytes in sweat, detection of viruses and pathogens such as Covid-19, blood testing for illness markers, and other medical applications. The demand for microfluidic chips with screen printed electrodes inside of them will keep growing, as the demand for medical and biological information grows.

Send an email to [email protected] or fill out our contact form to get started on your custom microfluidic device with integrated screen printed electrodes. Sterling Electrode is set up for responsive design & engineering services, iterative prototyping, and high-quality mass production of your custom screen printed electrode